ARPA-E

THE VALPO TEAM AND FACILITIES

EXPERTISE

Thermal Sciences, Machine and Manufacturing Sciences, Electrochemical Science, Finite Element Modeling

FACILITIES

State-of-the-art 5 kW solar furnace, state-of-the-art manufacturing laboratory (i.e. CNC machining, 3D printing, and Plasma cutting), Gamry 3000 electrochemical work station, 490 Varion Micro GC, Rigaku MiniFlex 600 Benchtop XRD system, and high-temperature electric furnaces.

FUNDING

ARPA-E Light Metals Program;

Award No. : DE-AR0000421Highlights of Recent AccomplishmentsWhy the Electrolysis of MgO?Details of Latest Cell Concept and Expected Economics with Natural Gas as Thermal InputEconomic Information – Natural GasConcept for Solar Input

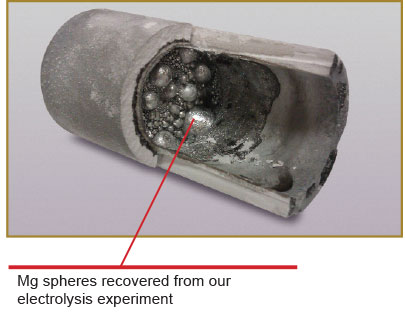

- We produced and recovered Mg by electrolysis of MgO in a molten fluoride.

- The cell operated with a current efficiency of 86 %

- The cell reached a current density of 0.5 A-cm-2 at 2.4 V

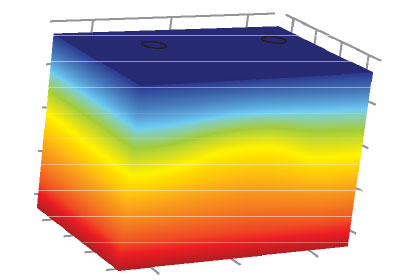

- Validated thermal input to cell via external heating and natural convection possible: h > 200 W/m2-K

- Magnesium is a valuable commodity with an expected rise in demand

- Electrolysis of MgO much less capital intensive than current MgCl2 process

- Cleaner, less energy and labor intensive than the Pidgeon process

SUSTAINABLE MAGNESIUM PRODUCTION PROCESS:

For:

(a) Lightweight Vehicles

(b) Recreational Equipment

(c) Casting

(d) Chemical Applications

THERMAL ENERGY DISPLACES THE ELECTRICAL ENERGY DEMAND BY AS MUCH AS 50%

Production level: 17,000 metric tons per year (requires 12 cells)

Description:

- Anode/Anode Bank

- Cathode/Cathode Bank

- Shroud

- Cathode Chamber Inlet

- Anode Chamber Inlet

- Cathode Chamber Argon Outlet with Flash Vaporization

- Anode Chamber Argon Outlet and Anode Electrical Connection

- Cathode Electrical Connection

- $32.5 million – Capital

- $2.38/kg Mg – Operating Cost (today’s dollars)

- 6.48 kWhr/kg Mg – Processing Energy

- 2.5 kg CO2/kg Mg – CO2 Emissions

Contact Information

Robert D. Palumbo Ph.D.

Alfred W. Sieving

Chair of Engineering

Professor of Mechanical Engineering

Valparaiso University

P: 219.464.5107

Email: robert.palumbo@valpo.edu

Project Partners

- Chrysler Group LLC

- Navigant Consulting Inc.

- Diver Solar LLC & Professor Peter Kissinger at Purdue University

- Institute of Inorganic Chemistry Slovak Academy of Sciences