- WHEN WILL MY PACKAGE REACH ITS DESTINATION?

- HOW LONG DOES IT TAKE BANANAS TO PASS THROUGH QUARANTINE IN U.S. CUSTOMS?

- WHERE DO YOU SOURCE RUBBER SUSTAINABLY AND ETHICALLY?

- HOW MUCH TOILET PAPER IS TOO MUCH?

- WHY ARE GAS PRICES GETTING SO HIGH?

- VALPO’S ALUMNI LEARN TO ASK AND ANSWER LIFE’S BIG QUESTIONS WITH A NEW DEGREE IN SUPPLY CHAIN MANAGEMENT.

We know every time we pick an item up off a store shelf that the goods we often take for granted did not appear by magic. At some level, we’re all vaguely aware that an intricate network of trucks, trains, airplanes, and cargo ships are in constant motion around the world to make our consumption of these products possible. The impact of world events, including COVID-19, trade wars with China, and conflict in Ukraine, have tuned that vague notion of the supply chain into a major logistics problem for manufacturers and consumers alike. As costs go up and availability of some items goes down, Valparaiso University’s College of Business is working hard to train future industry leaders to tackle new challenges.

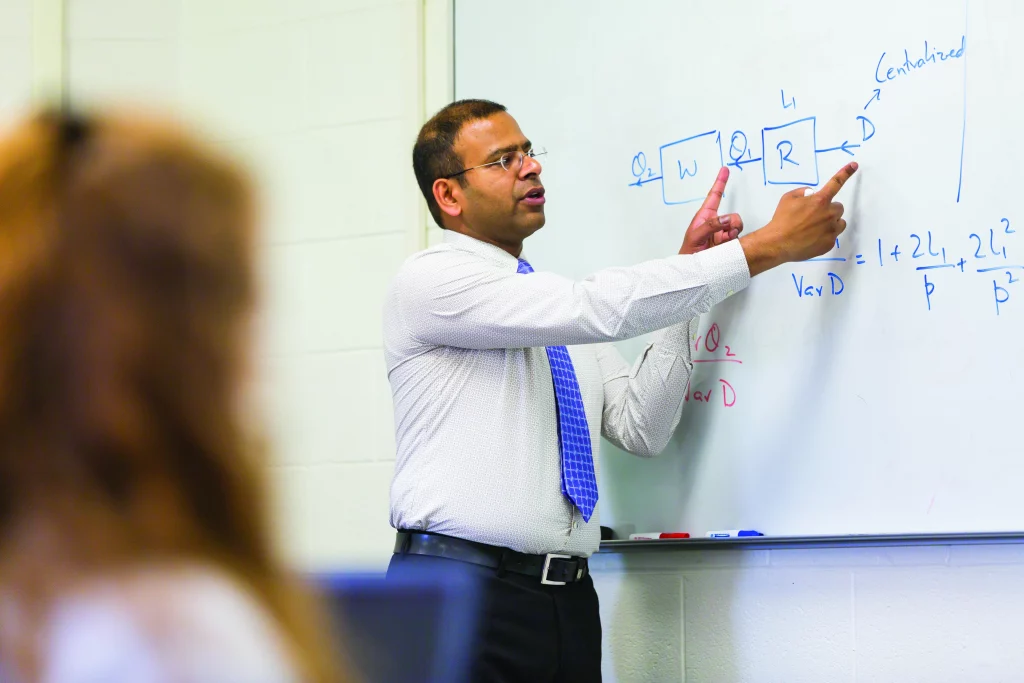

Sanjay Kumar, Ph.D., Richard E. Meier Endowed Professor of Management and professor of information and decision science, is leading the way toward training the future supply chain workforce and establishing the supply chain management and logistics major at Valpo. The program, currently the only one of its kind in the region, is the latest step in an academic journey that Professor Kumar has been on for most of his life.

“Looking back on it, I knew I wanted to be a professor from about middle school,” Professor Kumar says.

Despite knowing where he wanted to take his love for research and academia, the decision to dedicate himself to supply chain management did not come until midway through his academic journey. Professor Kumar received his B.S. in industrial engineering from the MBM Engineering College and a master of technology from the Indian Institute of Technology in Kanpur, India. While studying industrial engineering, he discovered a passion for supply chain management. On the surface, the shift in professional interests may seem drastic, but according to Professor Kumar, the two areas are more similar than they appear.

“Industrial engineering is the engineering equivalent of supply chain management,” Professor Kumar says. “They apply the same principles of optimization and management on a machine level, while supply chain management does the same thing on a business level.”

Professor Kumar threw himself into the academic field of supply chain management, obtaining his M.S. and Ph.D. from the University of Texas at Dallas. His area of specialization is in disruptions to the supply chain.

“When things go wrong, what are the consequences?” Professor Kumar asks. “What can be done to minimize the impact of these disruptions?”

One of the major issues that Professor Kumar researched in terms of disruption to the supply chain was the Sept. 11, 2001, attack on the World Trade Center. While the humanitarian tragedy and political impact of the event were both horrible and long-lasting, the day also had a profound impact on business and the supply chain.

“On that day, all of the airports and shipping ports were closed,” Professor Kumar says. “International shipment became extremely difficult. Then the recession followed, and consumers were not buying goods.”

The United States Department of Homeland Security contacted Professor Kumar shortly after the events of 9/11 to evaluate the necessity of strengthening the U.S. supply chain. Specifically, Professor Kumar was to project what would happen in the event of a similar terrorist attack aimed at critical infrastructure, and to project how long such an attack would impact the economy.

His findings have shown that it did not take a long disruption, in terms of days or weeks, to have an immense impact on the supply chain, with a mere 10 days of disruption likely resulting in at least two to three years of difficulties for the impacted industries. In a more recent example, the power outages in Texas during the winter of 2021 resulted in a disruption to the furniture industry, as cushioning for the majority of sofa manufacturing are produced in the state. The impact of that disruption is still being felt in the industry today.

Professor Kumar’s work for the Department of Homeland Security won several awards, including “Best Paper” by a number of academic organizations.

PAST LESSONS, MODERN CONSEQUENCES

According to Professor Kumar, many of the core principles he worked with while researching the economic impact of 9/11 are similar to the impact of the COVID-19 pandemic on the global supply chain. Factors including supply and demand, international shipping, and breaks along the manufacturing chain are major players in both events. In other ways, however, the events are the complete opposite of one another.

“In a way, everything involved with COVID-19 has been the opposite of the recession,” Professor Kumar says. “After 9/11, the supply was high, but consumer demand was very low. With COVID-19, the supply is low due to manufacturing breaks and the labor shortage, but the demand is as high as it’s ever been.”

While this gap between supply and demand has meant a greater burden on the consumer’s wallet, Professor Kumar says that the industries themselves have not seen a loss in profits, as high demand and scarce supply have allowed companies to raise the prices of goods significantly.

“For example, auto manufacturers had a chip shortage. So while they could not make the cars, they could sell what they had at a much higher price,” Professor Kumar says.

Despite surface-level profits, Professor Kumar believes that the current state of the global stage will incentivize companies to change the way they do business, especially in terms of how they approach globalized manufacturing. An active member of the Association of Supply Chain Management (ASCM), a global leader in supply chain organization and innovation, Professor Kumar gave a presentation to the organization in May regarding his predictions for the future of many global industries.

“My first point was that I believe globalization will look very different in the next 10 to 20 years,” Professor Kumar says. “Businesses in the past have thought that governments could go ahead and not agree on things, and the business world did not care.”

That perceived lack of a relationship between international governments and businesses has been shaken up in just the last few years by a number of events including not only COVID-19, but also recent trade wars and the Russian invasion of Ukraine. These events have demonstrated to industrial giants that simply operating wherever the labor is cheapest, regardless of that country’s political situation or relationship with the rest of the world, may not be the optimal plan for their businesses moving forward.

The second major point Professor Kumar made during his presentation was in regards to the actual cost savings manufacturers are seeing by moving production of goods to countries like China and India, banking on the cheap labor to save them money. According to Professor Kumar, many businesses outsourced their production labor, not due to careful thinking or deep analysis of the benefits, but simply because they saw their competitors doing it.

“Outsourcing became more of a trend than a smart, thoughtout business decision,” Professor Kumar says.

It is a trend that is starting to show its flaws. As labor costs in China rise, the profits seen from outsourcing manufacturing drop. The cost of shipping goods from China to the U.S. has multiplied, with Professor Kumar estimating that sending a small box between the two countries, an act that previously cost just 30 cents, would now cost a manufacturer at least five times as much.

“A lot of companies went for globalization to save money,” Professor Kumar says. “We’re now seeing that it isn’t happening.”

WHERE COMMERCE GOES FROM HERE

While Professor Kumar does not believe that these factors will necessarily lead to all manufacturing coming back to the United States specifically, he does feel that the future of manufacturing may be closer to home than it is now.

“The future will be less globalization like the type we’ve previously envisioned and more about regional bodies,” Professor Kumar says. “We’re going to see more groups of friendly countries trading with each other.”

Professor Kumar also predicts that artificial intelligence and robotic manufacturing will play a big role in shaping the future of the manufacturing industry and the supply chain, as labor costs are replaced by machine costs, and the idea of having those machines in the United States or Mexico may become the more attractive financial option.

Another major issue facing both the supply chain and the consumer alike is the gasoline shortage. While everyday commuters may be feeling the strain of ever-increasing gas prices, the supply chain made up largely of cargo ships and semi-trucks are being hit just as hard. Whether it’s personal or commercial drivers, everyone is looking for some kind relief at the pump.

“I don’t think the prices are coming down anytime soon,” Professor Kumar says.

I THINK THE PEOPLE IN THE SUPPLY CHAIN PROGRAM HAVE A VERY GOOD FUTURE…THE INDUSTRY DEMAND IS EXTREMELY HIGH, AND THE SUPPLLY IS VERY LOW

SANJAY KUMAR, PH.D. RICHARD E. MEIER ENDOWED PROFESSOR OF MANAGEMENT AND PROFESSOR OF INFORMATION AND DECISION SCIENCE

While disheartening on the surface, Professor Kumar maintains some optimism that the current gasoline situation could end up having a positive impact on the world at large. As businesses involved in the supply chain look at projections where gasoline remains high, they may find incentive to pursue more sustainable ways of powering their businesses.

“In five to 10 years, we may see what’s happening now as a good thing,” Professor Kumar says.

Professor Kumar believes that understanding the issues facing the supply chain today will be key to developing strategies that can keep it stable and robust in the future.

“A lot of companies know that COVID-19 will not be the last issue they will have to face,” Professor Kumar says. “There will be something else that comes up next year, or the following year.”

One issue these companies are facing is the lack of an avail- able workforce specifically educated to work in supply chain management and logistics. According to Professor Kumar, the majority of professionals currently working in those positions were educated and trained for other jobs within the industry and have been pushed into their roles out of necessity. Of those professionals currently working in the field, ASCM estimates that 25-30% are at or nearing retirement age.

HOW VALPO MAKES A DIFFERENCE

The Valparaiso University supply chain management and logistics program will help ensure that the indus- try has the trained professionals needed to tackle whatever future challenges and disruptions come to face the supply chain. Those students will also be taking the opportunity to enter a lucrative and in-demand field.

“I think the people in the supply chain program have a very good future,” Professor Kumar says. “The industry demand is extremely high, and the supply is very low.”

In 2019, the Department of Labor estimated that supply chain management and logistics related jobs would grow by 30% by 2030, higher than the growth rate of any other field. That estimate has only increased as the impacts of COVID-19 and other world events have shaken manufacturing and business. Through location, connections, and curriculum, Valparaiso University students have an incredible opportunity to enter into that rapidly growing career path.

Indiana’s state motto is “Crossroads of America,” and sit- ting in the northwest corner of state, near Chicago and Lake Michigan, the Valparaiso area is uniquely positioned for anyone interested in logistics and commerce. This one of the reasons Professor Kumar chose to join the University faculty and put together the supply chain management and logistics curriculum.

“This region has a lot of logistic and supply chain jobs, companies in the field, and the need for qualified graduates,” Professor Kumar says. “This is a region where this kind of program is very much needed.”

The supply chain and logistics curriculum Professor Kumar created is unique in that it takes the academic rigor seen in programs from other institutions around the country and actively adds the specific qualifications and training for which today’s employers are looking.

WE’VE ALWAYS UNDERSTOOD HOW CRITICAL THE SUPPLY CHAIN IS, BUT IN THE PAST TWO YEARS, WE’VE REALIZED WHAT A NECESSITY IT IS TO HAVE DEVELOPED LEADERS WHO UNDERSTAND THE PRESSING ISSUES.

“When I was developing the curriculum, I benchmarked the program with other major schools,” Professor Kumar says. “Then I took that curriculum to industry partners and asked for their input. We implemented their changes, and they certified the curriculum.”

By achieving this unique certification from industry leaders, companies in Northwest Indiana and the Midwest can be assured that graduates of Valpo’s program are trained to do the exact jobs that their businesses need, opening exciting doors for alumni to jump-start their careers.

“Companies want workers with supply chain expertise, and we’re producing those graduates,” Professor Kumar says.

Professor Kumar’s connection with ASCM has also helped boost Valparaiso University’s ability to foster the supply chain experts of tomorrow with a generous scholarship award, providing $6,000 to students in the program with a history of academic excellence.

OUR SUCCESS STORIES

One of those degree recipients is Keenan Burgess ’22, a recent graduate of the program who took a job with NVent, an electronics and construction manufacturer with locations around the U.S. Keenen is currently working in Solon, Ohio, as a lean analyst as part of the supply and operational leadership program. There, he will work to minimize the amount of inventory the company has on-hand, making sure they aren’t needlessly stuck with products that they cannot use or sell.

Keenan originally came to Valpo to join the swim team and study managerial accounting. While his initial ambition did not turn out to be what he hoped for, the variety of experiences offered by the College of Business helped him find his real path.

“I really hated the accounting part,” Keenan says. “But our class did a project where we created a pretend bicycle business, and I was put in charge of the manufacturing aspect of the project. That’s where I really fell in love with the supply chain aspect.”

Keenan’s change in academic pursuits took place right as the world went on lockdown due to the COVID-19 pandemic, which helped him realize the importance of the field he was pursuing.

“We’ve always understood how critical the supply chain is, but in the past two years, we’ve realized what a necessity it is to have developed leaders who understand the pressing issues,” Keenan says.

Gabriel Lawson, another ASCM scholarship recipient with goals of starting his own logistics company after graduation, appreciates how the program has helped him develop beyond academics.

“Valpo helped me grow personally by helping me become a better leader,” Gabriel says. “It helped me understand my place in the classroom, in public, and on the football field.”

Keenan says that the leadership opportunities at Valparaiso University played a major role in securing his current job.

“I was able to do so much in four years,” Keenan says. “At Valpo, you can be the president of one organization, the vice president of another, an athlete, and a student. My interviewers were highly impressed by that.”

Working with Professor Kumar was another highlight of Keenan and Gabriel’s experiences with the program.

“He’s one of the most involved and connected professors here,” Keenan says. “He understands the academic side, and the business side, as well as the requirements companies are looking for when hiring.”

“Professor Kumar helped me, not just in my field, but in making me a better human being,” Gabriel says.

Keenan’s current position has him moving to different branches of the company on year-long rotations. Over the next two years, he will learn about different aspects of the field in Minnesota and California. Wherever he goes, Keenan will bring his pride in his alma mater with him.

“I’m excited to show the quality of the Valpo College of Business supply chain management program,” Keenan says. “I’m one of the first graduates, and am getting out there to show them what our school is about. I get to establish relationships with my management team, as well as help connect future Valpo students with people in the industry.”

Professor Kumar says that the need for trained leadership in the field, along with the quality of Valpo’s program and recent world events, will mean that future students will be as successful at finding work in the industry as Keenan was.

“Regional industries and Midwest industries, know that our curriculum has been vetted by various companies as something that they want to see in their employees,” Professor Kumar says. “COVID-19 as well has shown the value of the supply chain as a discipline and that’s not going away any time soon.”

The Valparaiso University supply chain management program emphasizes problem solving and negotiation skills, as well as giving students a global perspective and ability to maintain good relationships. The program gives students a foundation of arts, science, and global cultures while providing hands-on experience with software commonly found in the workplace, as well as requiring practical experience from an internship or other paid work experience.

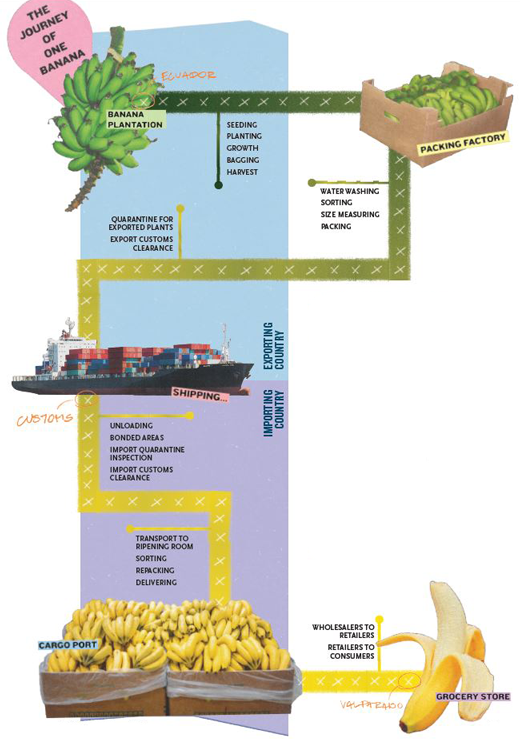

HOW DOES A BANANA GROWN ON A PLANTATION IN ECUADOR END UP IN YOUR MORNING OATMEAL?

The global supply chain is immensely complex, and at times, fragile. To illustrate the steps our goods undertake to reach our homes, look no further than the humble banana: From the country of origin to your table, the common banana can take quite the journey. Approximately 70-100 days after being cultivated, the banana is harvested and sent to a local packing plant to be washed, sorted, weighed, and packed for an international voyage. A temperature-controlled shipping vessel can take weeks to go from the country of origin to the United States, where the banana is then brought into quarantine and allowed to ripen. Finally, the fruit is chilled, packed up for a final time, and shipped off to supermarkets near you.

Delays at any step of the process can lead to low supply and thusly, increased prices. Students in Valpo’s supply chain management program gain an understanding of the problem- solving skills necessary to navigate the complicated processes that keep the global supply chain running smoothly.

Information for this graphic sourced from: www.nipponexpress.com/press/report/06-Nov-20.html